Other Variations

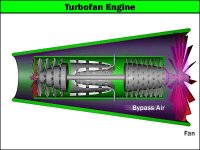

Large jetliners use what are known as turbofan engines, which are nothing more than gas turbines combined with a large fan at the front of the engine. Here's the basic (highly simplified) layout of a turbofan engine:

You can see that the core of a turbofan is a normal gas turbine engine like the one described in the previous section. The difference is that the final turbine stage drives a shaft that makes its way back to the front of the engine to power the fan (shown in red in this picture). This multiple concentric shaft approach, by the way, is extremely common in gas turbines. In many larger turbofans, in fact, there may be two completely separate compression stages driven by separate turbines, along with the fan turbine as shown above. All three shafts ride within one another concentrically.

No comments:

Post a Comment